The grooved design of the coupling provides a secure connection that can withstand high pressures. It evenly distributes the load,minimizing stress concentration and reducing the risk of leakage or disconnection. The grooves also help to maintain alignment between the couplings, ensuring a consistent flow of fluids or gases.

Grooved high-pressure hose couplings are commonly used in industries such as firefighting, oil and gas, mining, and

industrialoperations that require the transfer of large volumes of fluids under high pressures. They are often utilized in applications such as water supply systems, oil and gas pipelines, and industrial processes.

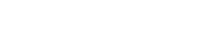

It is important to select the appropriate size and material for the LDHC coupling based on the specific application requirements. Manufacturers offer a range of sizes and materials, including stainless steel, aluminum, and ductile iron, to ensure compatibility with different hose diameters and operating conditions. Additionally, proper installation and maintenance procedures should be followed to ensure the longevity and effectiveness of the grooved high-pressure hose coupling.